1.6580; 30CrNiMo8; 30H2N2M

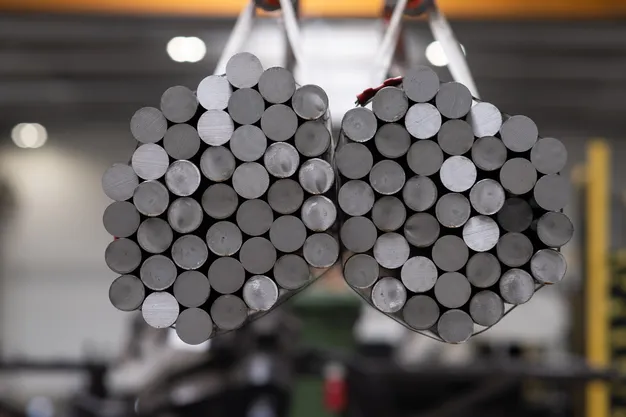

Steel for heat treatment

Dimensions:

from Φ 20 mm to Φ 250 mm diameter

Chemical composition:

| Element | C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| min | 0.26 | 0.10 | 0.50 | max | max | 1.80 | 0.30 | 1.80 | max |

| max | 0.34 | 0.40 | 0.80 | 0.025 | 0.035 | 2.20 | 0.50 | 2.20 | 0.40 |

Equivalents:

| Wr.Nr. | PN | EN | GOST | AISI |

|---|---|---|---|---|

| 1.6580 | 30H2N2M | 30CrNiMo8 | – | – |

Delivery condition:

Round bars:

- +QT – quenched and tempered

Description:

Structural nickel-chromium-molybdenum alloy steel for toughening, including through-toughening. High mechanical stress resistance, hard to weld.

Applications:

Heavily loaded elements for car and motor construction. Aero-engine crankshafts, driveshafts, elements for large-size turbines, gears, connecting rods, pump & press shafts, steering elements, steam turbine shafts, rings.

Dimensions:

from Φ 20 mm to Φ 250 mm diameter

Chemical composition:

| Element | C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| min | 0.26 | 0.10 | 0.50 | max | max | 1.80 | 0.30 | 1.80 | max |

| max | 0.34 | 0.40 | 0.80 | 0.025 | 0.035 | 2.20 | 0.50 | 2.20 | 0.40 |

Equivalents:

| Wr.Nr. | PN | EN | GOST | AISI |

|---|---|---|---|---|

| 1.6580 | 30H2N2M | 30CrNiMo8 | – | – |