1.2379; X153CrMoV12; NC11LV

Cold work tool steel

| Element | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|

| min | 1.45 | 0.10 | 0.20 | max | max | 11.00 | 0.70 | 0.70 |

| max | 1.60 | 0.60 | 0.60 | 0.03 | 0.03 | 13.00 | 1.00 | 1.00 |

| Wr.Nr. | PN | EN | GOST | AISI |

|---|---|---|---|---|

| 1.2379 | NC11LV | X153CrMoV12 | X12 | D2 |

Round bars:

- +A – annealed

Flat bars:

- +A – annealed

Square bars:

- +A – annealed

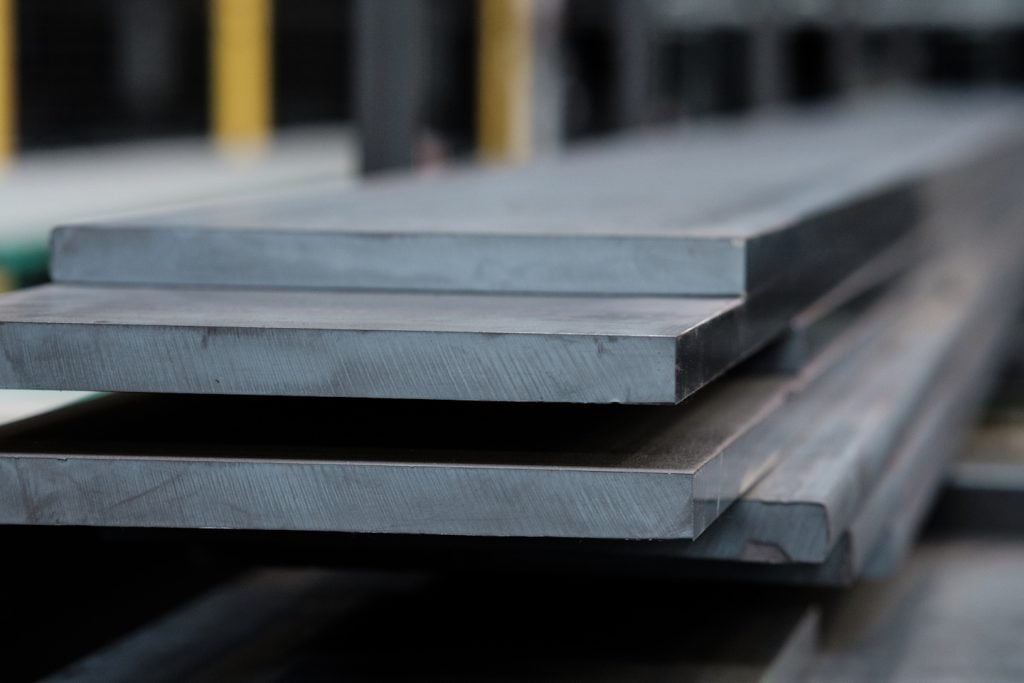

Sheet metal & plates:

- +A – annealed

Ledeburitic, chrome cold work tool steel, very highly resistant to abrasion, has higher impact resistance than grades 1.2080, X210Cr12 or NC11. Good ductility, great cutting properties. Does not deform during hardening. Significantly more durable than grades 1.2201, X165CrV12, NC10, 1.2080, X210Cr12 or NC11, thanks to molybdenum and vanadium content.

High-performance cutting tools, machining and piercing dies & stamps, woodworking tools, blades for cutting fine materials, thread rolling tools, tools for drawing, deep drawing & cold extrusion, pressing tools for the ceramic & pharmaceutical industries, cold-rolling working rollers for multi-roller workstations, measuring instruments & gauges, small moulds for plastics industry, where excellent abrasion resistance is required.

| Element | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|

| min | 1.45 | 0.10 | 0.20 | max | max | 11.00 | 0.70 | 0.70 |

| max | 1.60 | 0.60 | 0.60 | 0.03 | 0.03 | 13.00 | 1.00 | 1.00 |

| Wr.Nr. | PN | EN | GOST | AISI |

|---|---|---|---|---|

| 1.2379 | NC11LV | X153CrMoV12 | X12 | D2 |